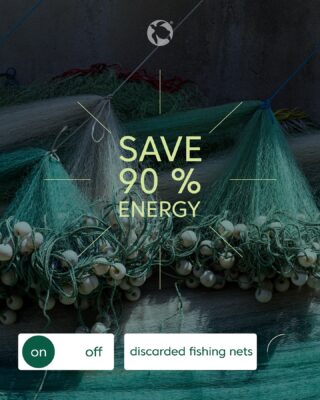

By transforming discarded fishing nets through natural processes, InResST saves up to 91% in CO₂ emissions, 90% in energy consumption, and 95% in water usage.

At InResST, we are committed to driving meaningful change for people and the planet.

our mission

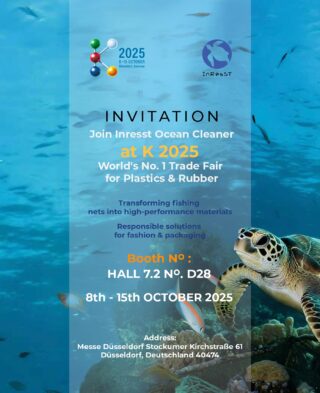

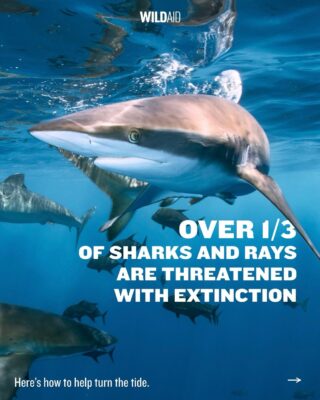

Cleaning Oceans, Protecting Marine Life, and Transforming Discarded Fishing Nets into Sustainable Solutions

By recovering discarded fishing nets from the ocean and transforming them through 100% natural processes into new products, we not only clean our seas but also safeguard vital marine life, including coral reefs, sea turtles, sharks, whales, and many more.

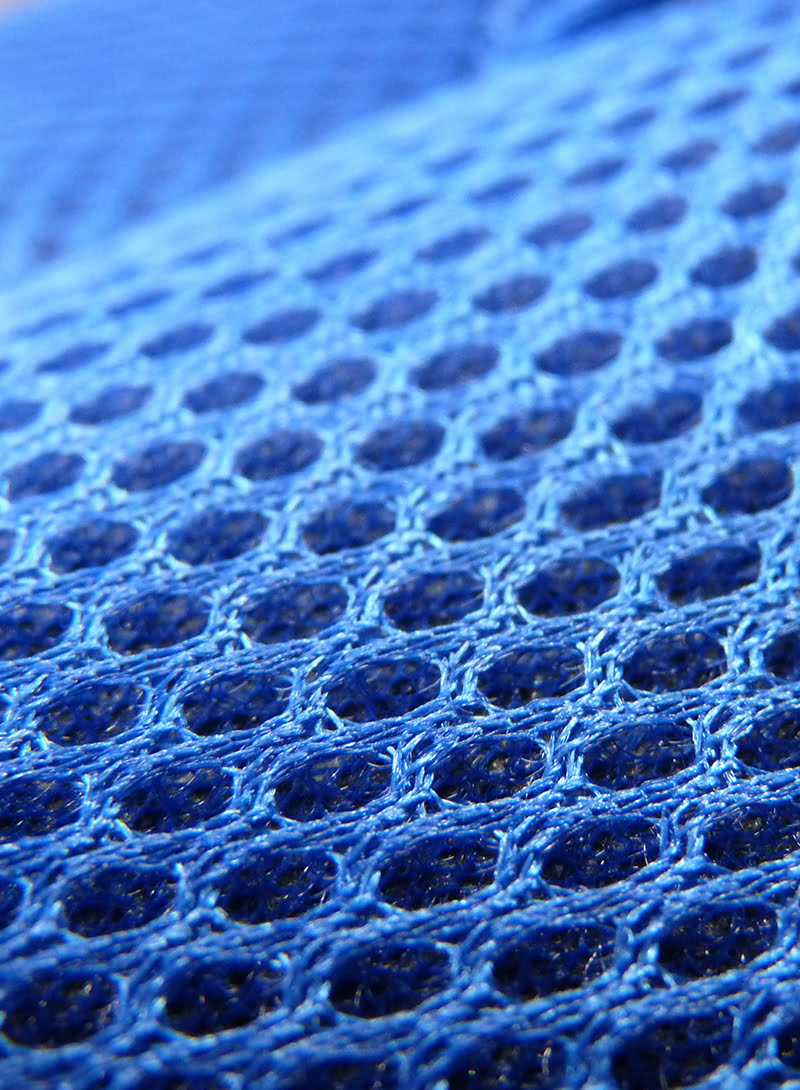

InResST® Recycle Materials & Applications

At InResST, we transform discarded fishing nets into high-performance, sustainable materials that serve a variety of industries.

Automotive & Industrial Applications

PP (Polypropylene)

Used in the car and automotive industry, providing durability, lightweight performance, and resistance to chemicals.

Fabrics & Fashion

PA (Polyamide)

Fabrics & Fashion Ideal for fabrics, garments, and fashion, offering strength, flexibility, and high wear resistance.

Sustainable Packaging Solutions

PE (Polyethylene)

Used for bags and skincare product packaging, ensuring flexibility, durability, and eco-friendly alternatives.

InResST Recycled Nylon is a premium, sustainable material derived from ocean waste, specifically fishing nets that have been discarded during deep-sea operations. Contribute to ocean cleanup by integrating our materials into your products.

environmental impact

What is the social impact of InResST® Recycle Materials?

By using recycled materials, InResST saves up to 91% in CO₂ emissions, 90% in energy consumption, and 95% in water usage.

New Research and Processes Shed Light on Carbon Emissions and the Lifecycle of Discarded Fishing Nets.

Our Cooperation With NGO

The importance of Sea Turtles to our Ecosystem

Sea turtles are essential to the health and balance of marine ecosystems. Their ecological roles span from maintaining seagrass beds and coral reefs to enrich coastal habitats.

"The ocean drives climate and weather, regulates temperature, and ultimately supports all living organisms. Protecting it isn't a choice; it's a necessity."

National Geographic Society